Our Reconditioning Process includes an in-depth, multi-point evaluation of every working component of the machine.

1. Gear Reducer – Inspect for external signs of bearing or gear wear, i.e. excessive shaft play, gear lash, seal leakage or bearing noise. Replace parts as necessary.

2. Vari-Drive – (if applicable) Check condition. Check for pulley wear and alignment. Align if needed. Check condition of belt; check operation of powered speed changer if equipped. Recalibrate blade speed indicator. Replace parts as necessary.

3. Hydraulic System – Check for leaks; inspect solenoid valves, cylinders, gauges, fittings, etc. Replace parts as necessary.

4. Cam Followers -(Dualcolumn machines)inspect and lubricate.

5. Blade Tension Assembly – Lubricate slider plate and adjust tension as necessary.

6. Hydraulic oil and filter -Inspect and replace as necessary.

7. Lubrication Points – Grease or oil all as required, i.e. idle wheel bearings, pivot points, guide rails, lead screws, pillow blocks and roller drive chain. Replace parts as necessary.

8. System & Cutting Pressures – Check and adjust.

9. Powered Blade Brush – Check for proper operation and replace as necessary.

10. Vises & Barfeed – Inspect all for vise plate wear and proper operation. Check operation and alignment of feed to saw.

11. Blade Guides – Inspect condition and replace as necessary.

12. Band Wheels – Inspect for excessive wear, crowning or taper and replace as necessary. Inspect idle wheel bearings and drive wheel run out. Replace as necessary.

13. Guide Arm Assembly – Check alignment, check that saw blade is square to vise and that the feed of the saw head is within specifications. Realign if necessary.

14. Blade Tracking – Inspect and adjust if necessary.

15. Feed System – Calibrate feed rate.

16. Coolant System – Check coolant pump operation and condition of coolant lines. Replace as necessary.

17. Electrical – Check all connections and secure if loose. Inspect cables and wires for fraying and insulation wear.

18. Control Switches – Check operation of all. Replace as necessary.

19. Limit Switches – Check adjustment and operation. Replace as necessary.

20. Final Run Off – Test run machine in all modes. Test cut and check parts for length accuracy and squareness.

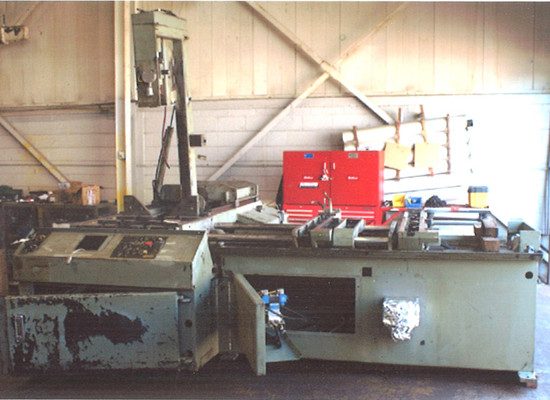

With over 50 years in the machinery sales business, Westbrook Engineering has the knowledge and expertise to determine the machines that best suit your needs. We put our bandsaws through a 20 Point Inspection and Repair Process, assuring you that your saw will hold proper length and squareness tolerances when it hits your shop floor. If you’re in the market for bandsaws, contact the bandsaw experts at Westbrook Engineering today. View our entire used bandsaw inventory.